| April 7, 2010 |

|

Fast

and accurate

determination of the dry matter content in wood chips with dual energy

x-ray

Mikael

Hultnäs, PhD student, Swedish

University of Agricultural Sciences,

Uppsala, Sweden. Mikael provided an overview of the Department of

Forest Products and presented some key findings from his PhD project,

"Scaling of Pulpwood". He showed the extensive work done on testing the

accuracy of the Mantex

device which provides moisture content and thus dry weight in real time

(less than one minute). In other words, no need to heat the chip

samples in a vented oven for 24 hours. The device can also

spot

contamination of non-wood material, e.g., rocks and metal.

The device

has proven itself to be very accurate in Sweden, both in single specie

applications (spruce) and in mixed species (spruce and pine.

Click

here to view the presentation.

|

|

|

The

variability of

weight scaling results

Kim Iles, Kim

Iles and Associates, Nanaimo, British

Columbia. Kim gave us the view on statistical sampling that you don't

find in the text books. He pointed out that we typically

miscalculate the sampling error when determining the sample

size needed for sample cruising or sample scaling. There is

nothing wrong with systematic sampling, such as prior load

sampling in log scaling or grids and other systematic methods of

cruising. Determining the sampling error of these systematic methods,

with formulas designed for random samples will overestimate

the sample size needed. The 95% confidence limit

(t =2) is misleading, with a more realistic confidence limit being t =

0.7; Finally, the result of the above is that we generally

over sample. Click here to view the

presentation.

|

|

|

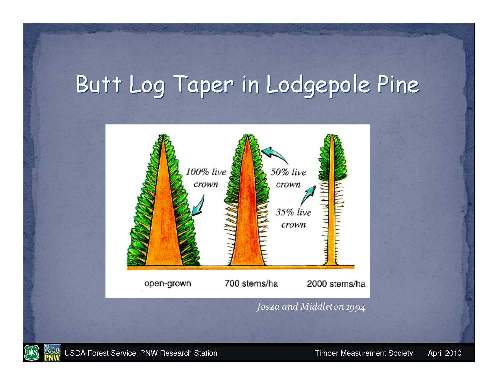

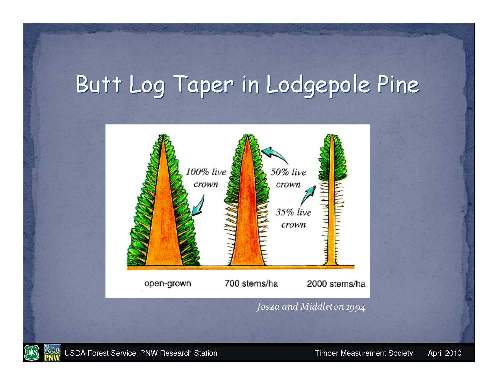

Rethinking

standard

taper rates for butt-cut logs

Eini

Lowell, USFS Pacific

Northwest Experiment

Station, Portland, Oregon. Eini showed the current

assumptions used in the USFS Region 6 taper tables for butt-cut logs

and how they compare with empirical data from other sources. Her

presentation focused on long (32'-40') lodgepole pine from regions

within and surrounding Eastern Washington. The results appeared to

indicate that the assumptions used in the Scaling Handbook for Region 6

east-side, Scribner scaling have the potential to overstate log volumes

by a significant amount. Further research is recommended and

needed. Click here to view the

presentation.

|

|

|

Onboard

truck weigh

scales as an alternative to using platform scales for weighing timber

Peter

Dyson, Researcher, FPInnovations

-Feric Division, Vancouver, British Columba. Peter gave the

background and results of a study that he worked on in the

Vancouver Island region of British Columbia. The aim of the

study was to assess the possibility of using onboard truck

weight scales as a substitute for platform scales. He showed

the advantages of using such a system and the results of their study

via a comparison of the net weight of the loads as measured by the

onboard truck scales vs. drive-on platform weight scales. The results

were very impressive, with 81% of the 280 loads (10, 644 tons or 9,654

tonnes) within + or - 1%. The total log weights as

measured by the onboard truck scales were +0.05% of what was determined

via the platform scales. Click here to view the

presentation.

|

|

|

Interfor’s

efforts to improve efficiency in measuring logs

Bruce

Moran, Scaling Supervisor, Interfor,

Campbell

River, British

Columbia. Bruce presented the ongoing process at Interfor to gain

efficiency in their log scaling processes and how these relate to

efficiency in other areas of their operation. He reviewed past and

current methods and efforts at improved efficiency. A current

focus is scanner based log scaling. They currently have a Microtec log scanner installed in

their Acorn, B.C. sawmill and are looking toward this technology as an

important focus for future gains in log scaling efficiency. Click here to view the

presentation. |

|

|

Measuring

biomass and other low value forest products

Frank Duran, R6 Measurements

Specialist, USFS,

Portland, Oregon. With the advent of bioenergy and other demands for

low valued fiber taken from the forest, the US Forest Service developed

a number of methods to measure these products. These were

developed with an eye to the accuracy standards, costs and the inherent

variability of measuring some of these products. The issues

and procedures that he covered were: "Low Value Policy" (June 2009), 3P

photo, slash piles, load count and weight, sample error policy and

random branch sampling. Click here to view the

presentation.

|

|

|

Measuring

logs on the

truck: keys to accurate and expedient truck scaling

Gary Baylous, Operations

Manager, Pacific

Rim Log Scaling Bureau, Lacy, Washington.

Gary presented the key ingredients necessary for accurate load volumes

when scaling on the truck. He showed the essentials in terms

of equipment, load presentation and scaling skills. Approximately 40%

of the volume that Pacific Rim scales is on the truck and when done

properly, truck scaling yields accurate volumes and provide some

advantages over ground scaling, in terms of reduced handling &

breakage. Click here to view the

presentation.

|

|

|

Log

scaling update

from New Zealand

John

Ellis, Group Technical Manager, C3 Ltd.; and Managing Director of

Scaling

Research International, Mount Maunganui, New Zealand. John gave us an

overview of forest management and harvest in New Zealand and C3's

scaling and log handling operations in New Zealand. He covered the

procedures used in the 3D method of scaling in New Zealand as

well as the 2D, JAS and Chinese systems. He also briefed us

on the situation with scaler employment, as well as standards used to

monitor scaling performance. |

|

|

Logmeter,

drive

through log scanning for volume and log attributes

Mario

Angel, WoodTech -

North America, Portland, Oregon. Mario provided background on the

WoodTech company, which is based in Chile, as well as installations,

worldwide, where their products are currently being used. He

showed the comparative advantages of their scanners, which measure load

volumes in real time, when a truck drives through their scanning arch.

The scanners can differentiate logs and chips from the truck

and trailer and even measure attributes such as log diameter length and

imperfections such as crookedness. The scanning arch can be

used to view the visible characteristics of the load (external logs),

which can be used to extrapolate the hidden logs, or with the addition

of back lasers, it can measure logs inside the load. Volume accuracy is

very good and can be utilized to calculate a board foot volume as well.

Click here to view the

presentation. View a short video on the Logmeter 4000. |

|

|

Tips for using the

latest technology for timber cruising

Bill Carr, LaserTech, Missoula, Montana.

Bill gave practical instruction on the use of the Impulse 200,

TruPulse 200/200B and 360/360B laser measuring devices for measuring

heights and distance, including procedures for those difficult

situations, such as through foliage or when the tree is leaning.

He also showed procedures for measuring crown cover and tree spacing.

He gave pointers on the use of the Criterion RD 1000

for measuring diameters (at different points on the stem) and variable

plot cruises. Finally he presented some of the useful accessories

that can be used with the impulse laser measuring devices, such as the

compass module and MapStar angle encoder. Click here to view the

presentation. |

|

| April 8, 2010 |

|

Timber industry

economic forecast

Henry Spelter, USFS Forest Products Laboratory, Madison, Wisconsin.

Henry gave a concise overview on the current situation with

credit boom, the North American and world economy, and how this

situation is currently affecting the forest products industry. He

concludes that in North America, housing and construction will improve,

thus increasing demand, gradually given the population increase and

immigration rates projected and that by mid-decade, much of the lost

demand will be back. In addition to this, there are other factors

at play such as increased offshore demand (e.g., China) , reduced log

supply in some regions , such as will be the case in B.C. because of

the mountain pine beetle, which all point to the potential of a strong

rebound in the next 2-3 years. Click here to view the

presentation. |

|

|

New USFS procedures

for using GPS on traverses surveys and new area determination standards

Gary Boyack, Forest Measurements Service Center, USFS, Fort Collins, Colorado. Gary reviewed the revisions being done to the Forest Service timber cruising handbook , FSH 2409.12,

section 50, which covers area determination used in timber cruising.

These include the use of GPS for the walk around method and the

corner method. The results of these revisions are that the new proven

technology and techniques are addressed and clarity has been improved

via the revision of confusing and conflicting instruction. Click here to view the

presentation.

Two Trails: a survey package for cruising

Gary also gave a presentation on a new beta surveying program for timber cruising, called Two Trails,

that they developed to assist cruisers: when GPS is not available, when

the canopy cover is too thick to get an accurate GPS reading, when in

deep canyons or when positional dilution of position (PDOP) is bad.

The system allows the mixed use of GPS and traditional traverse

survey. The program has companion versions in PC and mobile CE

format. It is freeware and is available free of charge here. Click here to view the

presentation on Two Trails.

|

|

|

|

Return-to-log models

for procurement and planning (product volume and value recovery)

Roy Anderson,

Senior Consultant, Beck Group, Portland

Oregon.

Roy gave a brief description of the services that the Beck

Group provides and then focused on RTL (return to log models). He

described that an RTL is an extremely useful tool for a mill or

seller to determine the worth of logs of a particular species, size and

grade. The model can be used for calculating what a mill can pay for

logs (stumpage and at the mill gate) given a desired profit and risk

margin, and it can be used as a tool for modeling possible scenarios,

such as different products, or different units of log volume measure,

etc. He described the process used to populate the model with

information that is taken from log tests and operation expenses

(milling and harvest and haul). Finally he described why there is so

much variation in log value as a result of diameter. Click here to view the

presentation. |

|

|

Log

yard inventory measurements: lessons learned

John Calkins, Scaling Supervision,

Simpson Timber Company,

Shelton, Washington. John presented the lessons that he has

learned while working on improving the physical log yard inventory

methods. The focus of this work was being able to accurately assess the

stacked measure volume of the log decks by taking accurate heights and

lengths (widths were known from the loads that went into inventory).

Additionally, it was important to come up with a system that one person

could do efficiently, that was straightforward to all, including

auditors, and thus could be replicated and checked. After many

trials with different systems, the TruPulse 360 appears to be the

perfect tool to accomplish these aims. Click here to view the

presentation. |

|

|

Using the Laser

Rangefinder for measuring log decks

Jon Aschenbach,

Resource Supply LLC.,

Beaverton, Oregon. Picking up where John Calkins left off, Jon

Aschenbach gave a presentation on the methods of using laser

rangefinders, such as the TruPulse 360 for measuring log deck volume.

Some of the advantages of this technology, over the old tape and

measuring staff, is that it reduces the time needed to measure a deck,

one person operation, can measure a wide variety of log decks, is

repeatable, accurate and can be safer. Jon has developed software and

techniques for using the laser rangefinder for log deck measurements

and was especially excited about the capabilities of rangefinders, such

as the TruPulse 360B which has a built in compass, which allows one to

shoot deck dimensions in numerous places on the deck from one

location. Click here to view the

presentation. |

|

|

The

use of CTLs, pre-bundling and weight to volume ratios in helicopter logging

David Horrax, Forester,

Columbia Helicopters Inc.,

Portland, Oregon. Typically, helicopter logging is associated

with areas where no mechanized equipment can access and thus logs tend

to be scattered randomly, often requiring complex and varied cable

hookups. Recently, however, Columbia has been hired to harvest some

sales where it was possible to get cut-to-length harvesters into the

sale area. This significantly increased production, as logs could be

pre-bundled and more fully manufactured (no limbs, etc.). In addition

the CTLs are able to calculate cubic meters of log volume, which allows

the use of weight to volume ratios to determine accurate log turn

weights, thus capatalizing on potential pay load capacity. Click here to view the

presentation. View a short video on heli-logging pre-bundled log turns. |

|

|

Is there a better way

to measure timber than the board foot?

Neal Hart,

Jendro & Hart LLC, Sunriver, Oregon. Neal made a compelling case

for cubic log scale rather than the board foot. He presented some of

the misconceptions regarding the board foot rules, such as: that board

foot log is the same as board foot lumber and that there is a single

factor for converting between cubic volume and board foot. Interestingly

enough he showed that two of the most common and erroneous assumptions

regarding cubic to mbf conversions (4.53 m3 = 1 mbf log volume; 2.36 m3

= 1 mbf lumber volume) are still used quoted and cited. He

pointed out that it is almost impossible to make any meaningful

analysis of mill recovery using board foot log measure and that many

costly mistakes have been made in the past as a result of the volume

misrepresentation of the board foot log rules. Click here to view the

presentation. |

|

|

Western hardwoods overview:

log measurement issues, value drivers, manufacturing

Rob Johnson, Western

Hardwood Association,

Camas, Washington. Rob presented an overview of the hardwood industry

in the Pacific Northwest, from the log yard to the final product. There

are six major species (and many more minor ones) of hardwoods processed

in the Pacific Northwest: red alder (by far the most important), big

leaf maple, birch, western ash, black cottonwood, and pacific albus

(which is a hybrid poplar grown in plantations). He showed the typical

merchandising and manufacturing process. Finally, he explained that

alder is typically graded under proprietary rules and since it finds

its highest worth and biggest demand in appearance applications rather

than structural, the grade is rather demanding, with fall down ending

up as pallet stock or chips. Click here to view the

presentation. |

|

|

Measuring carbon for

commercial purposes in wood and the forest

Steve Fairweather, Mason Bruce

& Girard, Portland, Oregon. Steve

presented his experience in conducting forest inventories for small

landowners at an accuracy standard that meets the requirements of the

Chicago Climate Exchange (CCX). The rules of the CCX stipulate

that the inventory estimate must have a 90% confidence interval that is

no larger than + or - 10%, the inventory must work with the Forest

Vegetation Simulator (FVS) growth model, and must be capable of

verification by CCX approved auditors. Two important pointers in

meeting the CCX standards is to stratify stands and consider using

large plots rather than small ones, as this will reduce

variability. Click here to view the

presentation. |

|

|

The challenges and choices for woodland owners in a "cap and trade" world

Mike Gaudern Portland, Woodlands Carbon

Company,

Salem, Oregon. Mike gave an overview of the work that Woodland Carbon

does to assist small landowners in getting into the voluntary carbon

market. This is accomplished by pooling together small forest blocks

held by individual landowners and assisting them with the forest

management options and inventory process. In addition, mike gave us an

overview of the process of getting paid to increase the carbon

storage in your timber stand and pointed out three important steps

in achieving this: develop a forest management plan that

increases the carbon storage of your forest, get certified (e.g.,

American Tree Farms), and conduct a forest inventory. Click here to view the

presentation. |

|

|

CT scanning (computer

tomography): optimization technology that can measure and map defects inside of

logs

Konrad Tschurtschenthaler, Microtec, Brixen, Italy. Konrad gave everybody an

introduction to Microtec. He

gave the historical background on the discovery, logic and use of the

x-ray, and provided an explanation on the technical application of this

technology to measure and map internal defects , such as decay, metal,

pitch pockets, knots, checks, shake, sapwood, heartwood and bark. This

technology (Tomolog) will not only allow the proper measurement

and net volume estimation, but will give a new form of mill

optimization whereby the mill can maximize grade yield. The log is

simply run through a scanner (even at high feed speeds) and the size

and location of the defects are known. The potential for this

technology is huge - on all accounts. Click here to view the

presentation. |

|

|

Scaling profile:

Hampton Affiliates

Richard Wilfong, Scaling Supervisor, Hampton Affiliates,

Salem, Oregon. Rich gave us a view into their operations in the US

(they also are in Canada), focusing on the five sawmills that they

operate in Oregon and Washington (Willamina, Tillamook, Morton, Randle,

Darrington). He briefed us on the size of their operations, log

yard and scaling ramp procedures as well as how they communicate and

receive data from the two scaling bureaus (Yamhill and Pacific Rim)

that take care of their scaling. They have an excellent log

information system, which is populated daily with deliveries , which

can be used to estimate inventory, spot any log quality issues from the

sale area and take care of any questions that they might have regarding

log attributes. Click here to view the

presentation. |

|

|

Bi-directional transfer of data and support files between the

hand held scale software on an Allegro MX

David Dean, Electornic Data Solutions, Jerome, Idaho. In

prior versions of their log scale systems, data, programs, and support files were

exchanged between the hand held scale software and the PC support software,

DataLink CE, with either ActiveSync, phone modem, or direct serial

connection. They now

have the ability to transfer data, programs, and support files over the internet

to DataLink CE using TCP/IP. David

demonstrated the bi-directional transfer of data and support files between the

hand held scale software on an Allegro MX at our meetings in Portland to a

laptop running DataLink CE in Jerome Idaho using our office internet connection. The

hand held connected to the internet using the wireless network in the

motel.

|

|

|

Forest product conversion

factors for North America and Europe: Why do sawmills in Europe average 56%

recovery,

and in North America only 47%?

Matt Fonseca, UNECE/FAO Timber Section,

Geneva Switzerland. Matt gave a presentation on the work that is

ongoing in the UNECE Timber section in the area for forest products

data harmonization which is important in understanding conversion

factors. The UNECE/FAO uses conversion factors for periodic "forest sector outlook studies" as well as for checking the accuracy of data that goes into the "timber database",

which has forest products production and trade statistics for North

America and Europe. The Timber Section recently completed a publication

on forest product conversion factors (Forest Product Conversion Factors for the UNECE Region).

Country experts (most of which were members of the Task Force on Forest

Products Conversion Factors) and correspondents submitted their

ratios. The results were interesting in that differences in the way

volumes are determined and at what point in the manufacturing process

(primarily roundwood and sawnwood) likely cause much of this

difference. In addition there is a short presentation on some of

the key findings of this project, which would suggest changes need to

be made to conversion factors that are used internally and printed as a

general guide in other publications. Click here to view the

presentation on conversion factors and here to view the presentation on data harmonization. |

|

|

| April 9, 2010 |

On April 9,

we had a field trip to the interfor mill in Mollala Oregon. Most took a

tour of the mill and participated in a comparison scale on a group of

35 logs. The logs included mix of typical Douglas fir and western

hemlock logs that are used at this mill, however, there were a number

of other species and large, highly defective logs thrown in to make

things interesting. This included a large western red cedar that was a

borderline cull or merchantable log (depending on how far the rot ran

up the log) as well as a large western hemlock log with twist and frost

cracks, which was considered to be cull by some and merchantable by

others. The median numbers for the logs were as follows:

|

BC

Firmwood m3

|

NZ 3-D m3

|

JAS m3

|

NWLRAG ft3

|

USFS ft3

|

Scribner Long log bf

|

Scribner Short log bf

|

|

Gross

|

Net

|

Gross

|

Net

|

Gross

|

Net

|

Gross

|

Net

|

Gross

|

Net

|

Gross

|

Net

|

Gross

|

Net

|

|

39.557

|

39.557

|

42.918

|

42.918

|

42.52

|

42.52

|

1607

|

1474

|

1394

|

1090

|

7155

|

4450

|

8710

|

6220

|

Given the small sample size

and the very high percentage of defect, which was not

representative, these numbers should not be used as any kind of an

indication as to conversion factors from one method to another, but

they are very interesting. It should be noted that there are

substantial differences in how these rules are applied. BC firmwood

only accounts for void, soft-rot and char, New Zealand 3-D and JAS are

not accounting for defect, while the NWLRAG cubic, USFS cubic, and the

two Scribner rules deduct for virtually all defects that reduce lumber

recovery, such as many firm defects, e.g., shake, cracks, crook, etc.

After the field trip, the group had a lunch at a local cafe in Molalla. The meeting was adjourned at about 2:30 PM.

|

|

|

|