|

|

|

|

Automatic

log scaling? Yes – and soon also automatic grading

– Lars Björklund (Head

of R&D; the Swedish Timber Measurement Council; Uppsala,

Sweden)

Lars gave

us the

background on the Swedish timber measurement council, of Sweden. Most

scaling is done by manned scanners (scalers record defect,

species, and grade) and at very high speeds

(1,000 pieces per hour). New

technology used includes: photo imaging to measure

ring-count, X-ray

technology for grades and log sorts, image analysis

to find rot, measuring MOE utilizing sound-waves, lasers are

being used to cube stacked volume of loads of pulpwood via a

drive-through, measuring pulp via photo imaging from cameras, harvester measurement

systems, and finally,

bone dry content of

chips is now measured via probes which can be hydraulically dropped

into loads

to get real time BD content and process the data into the payment

system. Click here to view the presentation.

|

|

Log

breakage study

and automated scaling implementation – Bruce Moran (Scaling

Supervisor, Interfor, Campbell River,

B.C.)

Interfor

studied why

some contractors had consistently better results than others.

Their assumption

is that a faller needs to produce about 100 m3 per

day (20 mbf) and

that 10% would be lost to breakage. What they found was a strong

correlation

with yarding tree-length logs and breakage, vs. yarding manufactured

lengths

and giving the fallers enough time “doing more and making

more value by doing

less”. Determining cost of breakage vs. cost of decreased

production was the

key to finding the balance. Having fallers remove broken log sections

in the

woods reduced the breakage further by eliminating the chance that

already

broken pieces would increase in severity due to handling. They also had

to

track performance of logging contractors. Their philosophy is

“people do what

you inspect, not what you expect”. Brad stressed that you

need the support of

management. Click here to view the presentation on managing log breakage.

Interfor’s

work on scaling via scanners is focused mainly on smaller second

growth logs. Interfor is working with the ministry of forestry on

approval and

already has equipment in place. The System measures the log after debarking (so

under bark

measurement not a factor). It has the advantage of not requiring the

removal of

log bundles from water storage until needed (saving log handling costs

and

reducing the associated breakage). Log load information (boom and block

identification) will be recorded during the dewatering and scanning

process. It

is commonly agreed that scanners are accurate for determining gross

volumes,

i.e., lengths are accurate to ½ inch over 60ft, diameters

are accurate to

approximately 1/8”. Currently accepted methods of measuring

diameters (rads)

create less accurate volume results than scaling by scanner, which

measures in

very small increments. A log could be scanned 100 times and the result

each

time would be extremely consistent. Future challenges with the system

includes

the scanners inability to see rot and grade, however, these are small

compared

to benefits. Click here to view the presentation on Interfor's automated log scaling system |

|

|

|

The secrets

to accurate acreage calculations – Jon Aschenbach

(Vice-President of Sales, Atterbury Consultants, Inc., Beaverton,

Oregon)

Jon

suggests

prioritizing the placement and number of timber cruise

plots. With GPS the acreage of timber stands can be

calculated with good accuracy. Some consumer grade GPS units ($70 to

$400) are

almost as accurate for acreage calculation as the $2,000 to $4,000

models. Jon

gave a live demonstration of the accuracy of this simple and

inexpensive GPS

system by showing the coordinates of the meeting room, tracking GPS

satellites

through the ceiling and roof of the building. Bottom line was that

given the

relative low cost of the new advanced GPS technology, data recording

hardware,

and data processing software, one can hardly afford to use the old

manual

methods given their lower levels of accuracy not to mention the

efficiency

issues. Click here to view the presentation.

|

|

|

Significance

and recognition of exotic insect pests in standing and harvested

timber – James LaBonte (Taxonomic

and Survey Entomologist, Oregon Dept.

of Agriculture, Salem, Oregon)

The number

one way that exotic wood

boring insects get introduced onto North America is through solid wood

packaging. Many are already

established in the US

and Canada

and are

here to stay (e.g., emerald ash borer). Imports are increasing and thus

the

incidence of exotic bark beetles are as well. Some

insect species can look very similar; with one being rather harmless

and the

other a serious threat. Unfortunately, the number of taxonomists is

decreasing

due to retirements and no new taxonomists are in the pipeline. Jim and

his

colleagues are using graphics to develop guides so

“lay-people” can identify

the threatening insects. Jim brought us up to speed on the exotic

insect

threats that are currently considered a threat to North America, or already are. Click here to see the presentation.

|

|

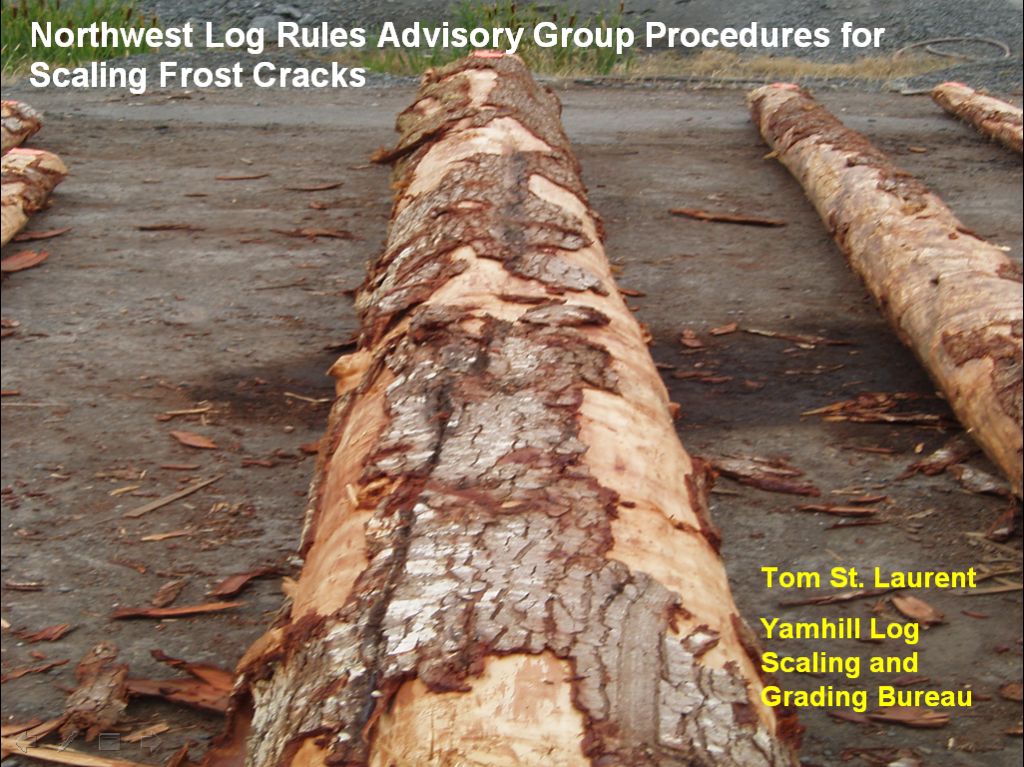

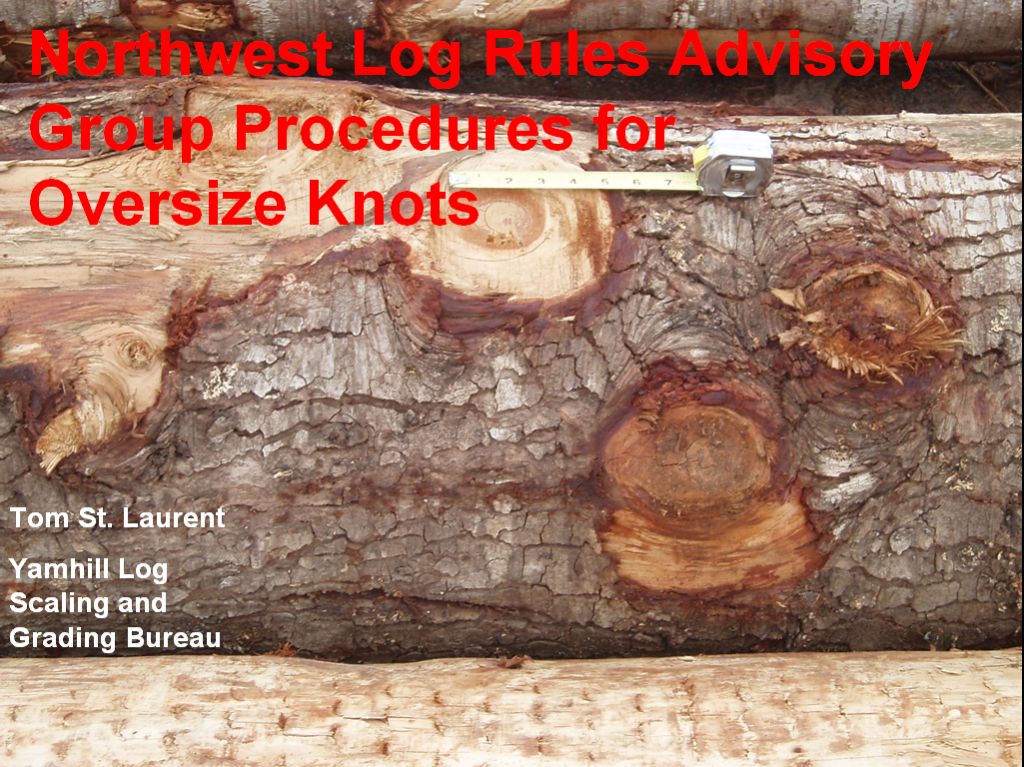

Scaling

deductions for logs with frost seams and grading logs with large

knots based on Northwest Log Rules Advisory Group (NWLRAG) –

Tom St. Laurent

(Manager, Yamhill Scaling Bureau; and Secretary, Northwest Log Rules

Advisory

Group, Forest

Grove, Oregon.

Tom

brought us up to speed on the developing NWLRAG rules for reducing volume and

grade for oversize knots and reduction of volume due to frost cracks (primarily

in western hemlock. Mill studies had determined that the current #2 sawmill

grade, which has an allowance of a 2 1/2” knot, was discovered to be too

lenient given the 65% construction grade lumber requirement, however, by

including the knot collar in young growth logs brought the grade back into

line. The current guidelines have improved the situation quite a bit. Scaler

variation is always a concern as knots characteristics have many different

degrees: size, density, placement, etc. Click here to see the slides on oversize

Frost

seams have been an ongoing problem in Hemlock. Generally scalers take a 1”

deduction for straight checks and pie-cut the spiral checks. This has helped in

the area of consistency, but more work needs to be done to determine proper

deduction, which is difficult to assess as all volume outside the scaling

cylinder is not to be considered when using Scribner scale. Bottom-line is that

things are better and more study is ongoing. Click here to see the slides on frost seams.

|

|

|

|

An overview

of log scaling in New

Zealand,

and some details of export (JAS) and domestic (3D)

scaling.– John Ellis (Group

Technical Manager, Toll Owens Logistics; and Managing Director of

Scaling

Research International, Mount Maunganui, New Zealand).

John brought us up to

speed on the overall status of the forest

products industry in New Zealand.

Some of the problems that the

industry is facing are the eroding value of the US dollar and increased

transportation costs. Export logs in New

Zealand

are scaled with JAS (Japanese Agricultural Standard), while most

domestic logs

are scaled via weight and the New Zealand

3-D method. Accuracy standards are +

or – 3%, scalers should agree on diameters with the check

scaler 62.5% of the

time and 95% of the log diameters should be within 2 cm. He gave an

overview of the scaling procedures

and methodologies for both JAS and 3D, which utilizes a unique formula

for

modifying stem form based on taper. Click here to see the scaling profile on New Zealand.

|

|

|

Scaling

study with artificial lights: can logs be scaled and graded accurately under

lights? .– Peter Dyson (Researcher, FPInnovations-Feric Division, Vancouver,

B.C.)

FPInnovations-Feric undertook a study to determine if logs could be scaled

accurately under artificial light conditions. As a starting point, they used 50

lux for young growth and 75 lux for old growth. The results were within 0.5%

excepting that the bigger more valuable grades, as a component, were outside

the tolerance. They then increased the lighting to 120 lux and the results

improved. Click here to see the presentation on scaling in dark conditions under artificial light.

|

|

|

The

“Quick Cruise” Option for

the Idaho Department of Lands – Steve Fairweather (Mason

Bruce & Girard, Portland, Oregon)

This was a

project done

by Steve for the Idaho Department of Lands (IDL), and called the

“quick

cruise”. The pilot project was done on 848 stands covering

70,000 acres. The

IDL wanted to use a “stand based” inventory but

found that it was too costly to

do it the conventional way. The system uses stratification, tallies

tries by

species or dbh (no heights, no defects). Quite simply, this system

takes

advantage of the relationship between basal area and volume. Uses Vq/Vs = BAq/BAs. So far

the IDL is very happy

with the results and expanding this method across their timber land

ownership. Click here to see the presentation.

|

|

|

Automated

log merchandiser/scaler

to measure and buck for most value – Andy Dick

(Director, Logjiztix, Whangaparaoa, New Zealand)

Logjiztix

purchased a

prototype machine that merchandizes stems by scanning a tree length

stem and

then cross-cuts it into the most valuable log lengths. This system

evolved from

a manual “caliper and tape” based system, which

showed a lot of promise, but

was too heavily reliant on a workforce that had limited technical

ability. This

processor does 70 loads (2,200 tons) of logs a day. The machine scans

length

and diameter and bucks stems into logs lengths that maximize value and

gives

detailed production data in real-time. The benefits include smaller

landings,

reduced field staff, reduced truck time, reduced harvest cost, improved

safety,

better on time deliveries, platform for further technology (x-ray, more

scanners, MOE testing), and improved log value recovery. The system has

been

thoroughly tested and has shown that it can dramatically increase

profits. Click here to see the presentation on the Logjiztix log merchandizer and here to see the technical paper on the system.

Andy

also brought a presentation on a portable tool for log scaling (the

Hitman sonic tester) which can measure the stiffness of the wood fiber

of a log and thus is able to determine wood with a high strength ratio,

which is suitable for LVL or stress rated lumber. It is a small

handheld unit the measures the speed of sound-waves that travel through

the log. Click here to see a presentation on the Hitman sonic tester.

|

|

|

|

Recovery

from simulated sawn logs with Sweep – Robert Monserud (Team

Leader – Forestry Science Lab, USFS Pacific Northwest

Research Station, Portland, Oregon)

Robert and

his colleague,

Christine Todoroki wanted to assess loss from sweep (assuming straight

sawing

in a sawmill) and if in fact there was loss from ovality in a sawmill.

For the

sweep test, real logs were mapped and then simulated with increasing

amounts of

sweep (and crook). This approach was chosen instead of actual empirical

log

tests because logs are too variable and thus results would never be

conclusive

as opposed to measuring and mapping a log and then simulating (via an

optimizer

program, Autosaw) the same log over and over again with increasing

amounts of

sweep. On average, recovery dropped 2.4% for each 1” of sweep

(determined “bow

string” method) for 16’ logs. Whether the sweep was

constant (sweep), or 4’

from the end (crook) the results of the study did not change. Click here to see the presentation on recovery of simulated sawn logs with sweep.

In

addition to the sweep study, Robert and

Christine studied the effects of ovality of species and ran simulations

of

various degrees of ovality, both in terms of comparison with round logs

of the

same size and in terms of rotation. On average recovery was

best when sawing parallel to the major axis

and contrary to many older references was a bit better than that of a

round log

with the same volume. Click here to see the presentation on recovery from oval logs |

|

|

|