|

|

|

Tribal scaling program update -

Thelma Alsup

(BIA Regional Log Scaling Coordinator/Check Scaler,

based in Warm

Springs, Oregon)

Thelma updated us on her work at

getting consistent tribal scaling

guidelines and certifying scalers and check scalers. She works with

various

tribes in the Northwest on the above and organizes roll-outs and

training. She

is also responsible for check scaling tribal wood. She coordinates

scaling with

government agencies and the private sector. Besides policy and scaling

budgeting for the tribes, she also works at making sure that the

scalers are

equipped with handheld data recorders and the appropriate software.

Thelma

represents 9 tribes. She will be looking at standard taper ratios on a

tribe by

tribe basis and is planning on setting up taper studies.

|

|

|

Log

data processing system - Bill McFarling (Black Hills Log System

Supervisor, Pope and Talbot, Spearfish, South Dakota)

Bill demoed their log data

processing system. The system manages truck

weigh-in including a sample tare weight system (whereby it randomly

selects

tare weights at a desired frequency) and has many safeguards to insure

that

weight is not accidentally or purposely manipulated. The system also

error-checks and gives an audit trail. It also selects sample scale

loads and

quality check loads at any desired frequency. The system verbally tells

the

truck driver where to unload the logs based on log sort and if from an

agency.

The system stores all individual log data and all load data. It has an

excellent load/log querying system whereby one can get almost any

information

quickly and simply. The system manages all log data and QC information,

tabulates the log yard inventory, and calculates payments to all

contractors

and landowners. The system is marketed by Round2 Consulting out of Boise

Idaho.

|

|

|

Cubic log scale: defunct or still

worthwhile – Rich

Ernst

(Forester, USFS

Forest

Management

Service

Center

in Fort

Collins Colorado)

Rich stated that the US

government stance, for federally owned timber, is that they are still

on cubic

and have no plans on deviating from that. There are a few caveats to

this in

that Alaska

and salvage sales are allowed to continue with Scribner. Their focus is

on tree

measure rather than scaling, and the new focus is on weight based

sales. He

stated that the official position is to not go back to board foot

measure and

that the USFS is committed to measuring timber volume in cubic units.

|

|

|

Biomass

and Stewardship sales

– Blair Moody (Forester, BLM, Ashland Resource

area)

Stewardship

contracts

allow the exchange of wood fiber for services rendered. Stewardship

sales are

not intended to replace the normal timber sales program. These sales

still have

to live up to the management standards such as NEPA, EIS, etc. The main

focus

is forest health and to mitigate fire hazard by removing small

commercial and

noncommercial trees, but can also cover noxious weeds, campground

maintenance,

etc. They collaborate with rural communities, businesses and other

agencies.

Biomass is also a strong focus, as these trees tend to be small and

government

policy is moving toward this direction given energy goals and demand.

Much of

the aims of this program come from the “Healthy

Forest

Initiative” and “Green Energy”. In 2005

they offered 71,000 tons of biomass

(10,000 in Oregon

and Washington).

In 2006 there will be

approximately 200,000 tons of biomass offered.

|

|

|

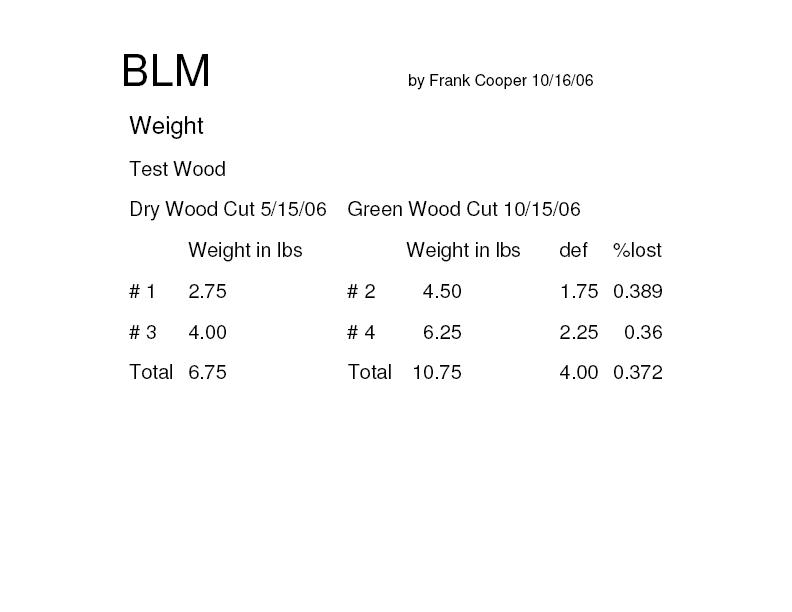

Weight

scale – Frank Cooper (BLM, Bend Oregon)

The BLM does not sell sawlogs via

weight, however, they do use

weight-sample scale, and weight for biomass sales. Frank has found that

weight

is being manipulated via leaving the logs on the ground on biomass

sales, which

are sold on weight, and thus has reservations regarding the usefulness

of it

(especially for sawlog sales) for selling BLM wood where the purchaser

has

flexibility to leave wood on the ground. Frank

presented some information which showed

that wood can lose more than 30% of its weight simply by letting it dry

out.

|

|

|

New

method of cruising biomass

– Dave Johns (Check Cruiser, USFS, R5, Quincy

California)

John developed a method using

orthoquads (satellite images that are

digitally corrected) to estimate cubic foot volume per acre. The system

is

based on 3-P and a density index (which was developed by Rich Ernst).

Basically

one estimates biomass volume from aerial photos and the estimate is

corrected

by sample cruising on the ground. They have found this system to be

accurate,

easily applied, and lower cost method of obtaining volume.

|

|

|

Scribner

log rules committee update – Frank Duran (in place of Camille Smith who was

unable to attend,

USFS Regional Measurements Specialist, R6, Portland Oregon)

Many of the Scribner log rules were

updated via the work done by the

Cubic Log Rules Committee research. Rules affecting oversize knot

deductions,

twist, pecky rot, pistol butt, forks, etc. These rule changes were done

to give

updated guidelines for any logs scaled via Scribner (salvage sales).

The

changes are effective immediately and will appear in the next variation

of the

USFS board foot handbook.

|

|

|

Weyerhaeuser

scaling profile: how

they handle log measurement – Mike Hayes (Scaling

Manager, Weyerhaeuser, Longview, Washington)

Mike

currently supervises the scaling process at the Lonview sort-yard and

has a 30+ year career in scaling and related areas. He went over the

changes he has seen at

Weyerhaeuser over his career, including the change to almost all

mechanized

logging. Weyerhaeuser uses both Scribner and cubic. Their scalers

undergo an

extensive scaling training program, which typically takes from 3-5

years. They

ship many logs to Japanese customers and some of the ships will haul

9.7 mmbf

on one ship. Their success in developing a strong customer base for

their logs

is based on their high expectations on log manufacturing quality,

highly

trained workers, and excellent feedback mechanisms to insure that

everybody is

aware of their performance.

|

|

|

State

of the art timber cruising,

a.k.a.

vertical scaling – Jon Aschenbach (Vice President of Sales,

Atterbury

Consultants, Portland

Oregon)

Jon

covered the current standard procedures and algorithms utilized in

cruising.

Jon demonstrated the new style reloscope, which works very well even in

dark,

low light stands. John covered the important areas of focus for

cruisers and

recommended that they spend time with scalers to learn about how they

handle

defect deductions.

|

|

|

The

drivers of product recovery

– Matt Fonseca (Manager of Log Utilization and

Lumber Quality Control, Plum Creek Timber Company, Columbia Falls,

Montana)

Matt covered the variables the

drive recover of particular products. He

showed how recovery of lumber, plywood, and residual products (chips,

sawdust,

shavings, bark) will vary given the type of mill (stud, dimension,

board, or

hardwood), the efficiency of the mill, specie, and given the

particulars of log

characteristics (diameter, length, taper, etc). He also covered how the

unit of

measure affects or even distorts product recovery.

|

|

|

|

| Jeff

Hedlund organized a great log roll-out at the Boise Building mill in

nearby White City. Many thanks to him and Boise Building for hosting

the rollout. There were 54 highly defective logs and it seems that one

of the intents was to give everybody a chance to utilize the new USFS

Region 6 supplement for twisted grain and oversize knots. I think we

all saw more twist and knot deductions in one day than we normally see

in a year. To see the logs that were bucked in order to better

ascertain the defect click

here. |

|

|